3D PRINTING DESIGN GUIDELINES

Introduction to Fused Filament Fabrication (FFF)

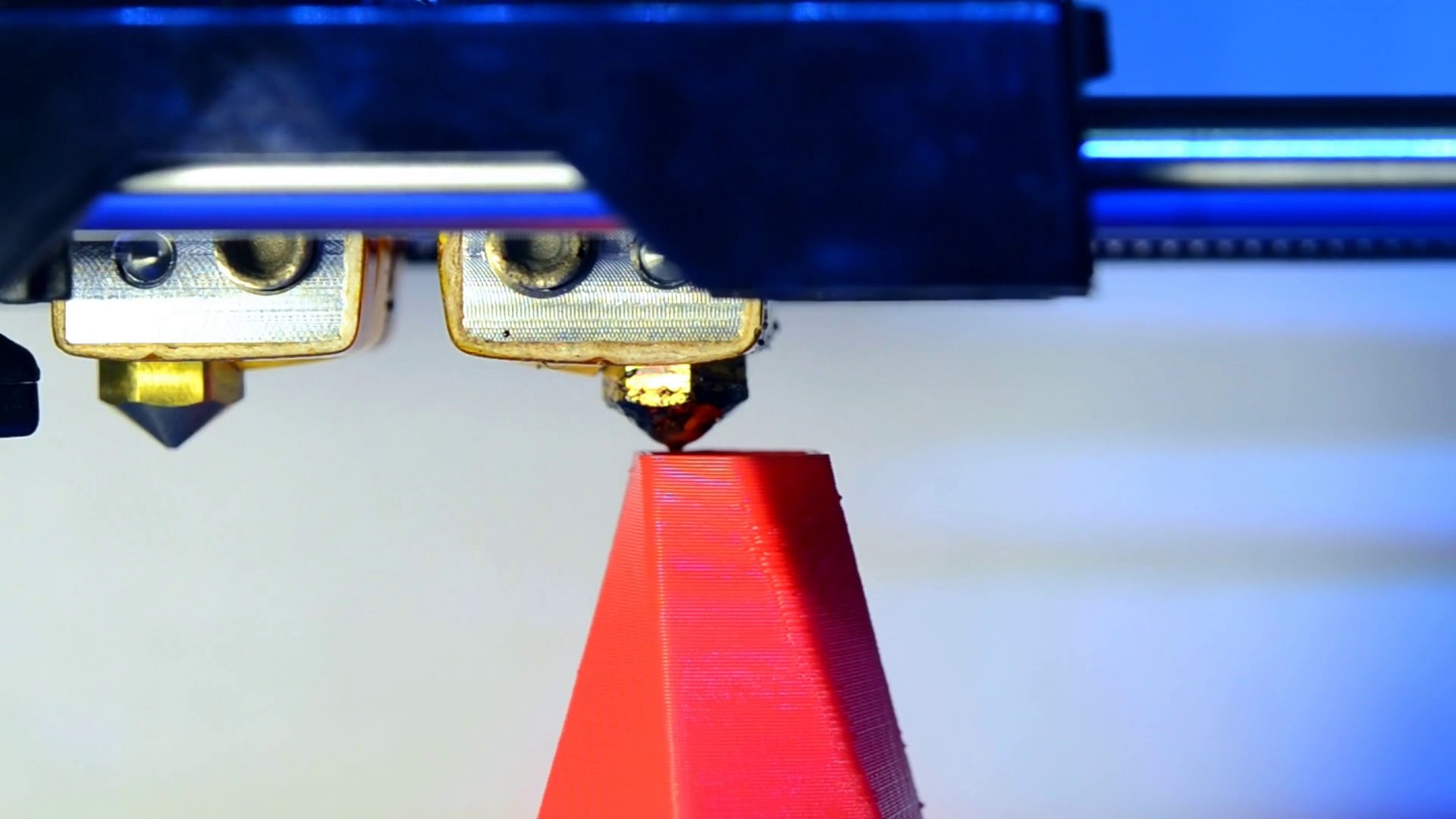

Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is a 3D printing process that creates objects layer by layer by extruding thermoplastic material through a heated nozzle. FFF is widely used for prototyping, manufacturing aids, and even functional parts due to its cost-effectiveness, material versatility, and ease of use. To achieve the best results with FFF printing, it’s essential to follow specific design guidelines tailored to this technology.

Key Design Considerations for FFF Printing

Wall Thickness

Minimum Thickness: Ensure walls are thick enough to provide structural integrity. A minimum of 0.8 mm is recommended for most materials, corresponding to two nozzle passes for a typical 0.4 mm nozzle.

Uniform Thickness: Aim for uniform wall thicknesses where possible to reduce stress points and warping.

Overhangs and Supports

Overhang Angle: Limit overhangs to 45 degrees or less to avoid the need for support structures. Overhangs beyond this angle may require support material, complicating post processing.

Design for Removal: When supports are necessary, design with removal in mind. Consider easy-to-remove geometries and strategic placement.

Bridging

Span Length: Keep unsupported horizontal spans (bridges) short, ideally less than 5 mm. Longer spans may sag or fail without support.

Holes and Gaps

Diameter: For holes, design slightly larger than the intended size to compensate for material shrinkage and layer adhesion. A 0.2 mm increase in diameter is a good starting point.Orientation: Vertical holes print better than horizontal ones due to support requirements for the latter.

Layer Height and Orientation

Layer Height: Selecting the appropriate layer height is crucial. A smaller layer height increases detail but extends print time. A height of 0.1 to 0.3 mm is standard for FFF.Print Orientation: Orient parts to minimize overhangs and supports while considering the part’s intended use. Vertical orientation increases Z-axis strength but may reduce detail and surface finish on curved surfaces.

Infill and Top Layers

Infill Percentage: Adjust infill based on the required strength and material usage. Typically, 20% is sufficient for prototypes, while functional parts may require 50% or higher.

Top Layers: Increase the number of top layers to ensure a smooth finish, especially for parts with flat surfaces. Four to six top layers are generally recommended.

Material Selection

Material Properties: Choose a filament that suits the part’s application, considering factors like strength, flexibility, and temperature resistance.

Shrinkage and Warping: Account for material-specific characteristics such as shrinkage and warping. Materials like ABS require careful temperature control and bed adhesion strategies.

Conclusion

Designing for FFF 3D printing requires an understanding of the process’s capabilities and limitations. By following these guidelines, designers can optimize their models for successful printing, resulting in parts that meet functional and aesthetic requirements. As you gain experience with FFF printing, experiment with settings and designs to push the boundaries of what’s possible with this versatile manufacturing technique.

3D Printing Services List

Experience true cutting-edge 3D technology with our range of services at Innova 3D, LLC. where innovation meets practicality, ensuring every creation is not just a print but a masterpiece of precision and quality.

Fused Filament Fabrication (FFF)

FFF is a 3D printing process that involves feeding a continuous filament of thermoplastic material through a heated extruder. In this method, the filament is melted and extruded layer by layer to construct a three-dimensional object. This technique is notable for its versatility and ease of use, making it popular for both hobbyist and professional applications in creating detailed, customizable objects.

We support a broad range of 3D printing materials including PLA, ABS, ASA, Polycarbonate, Carbon Fiber, Nylon, PETG and more.

High Definition Printing Utilizing SLA (Stereolithography)

SLA is a 3D printing technology that uses a laser to cure liquid resin into hardened plastic in a process called photo polymerization. This method allows for extremely high-resolution printing, capable of producing parts with fine details and a smooth surface finish. SLA is particularly favored for applications that require precise geometries and intricate details, such as dental work, jewelry design, and prototyping for various industries.

We include the following for service:

FormLabs Clear Resin, FormLabs Flexible Resin, FormLabs Elastic Resin, FormLabs Tough Resin, FormLabs Draft Resin.

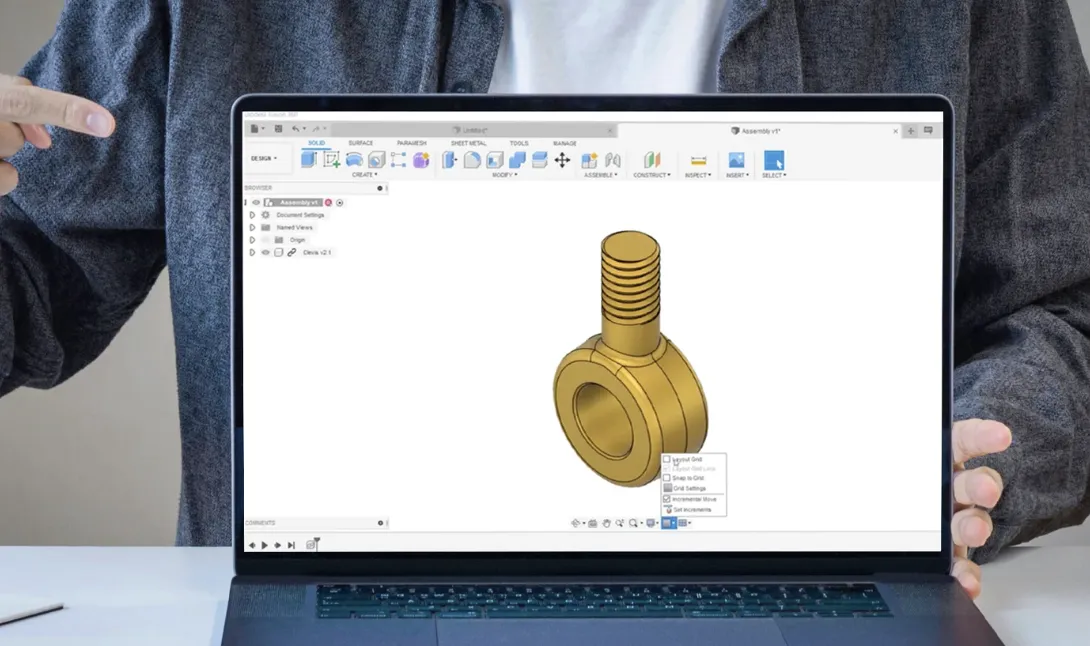

CAD Design and 3D Sculpting

Combining CAD Design's technical precision with 3D Sculpting's artistic detail, we swiftly transform initial sketches into detailed digital models. These models are then brought to life through advanced 3D printing, materializing concepts into tangible objects with speed and efficiency. This streamlined process showcases the synergy between digital design and physical manufacturing, ideal for rapid prototyping and custom creations.

Transform your simple picture into a sophisticated 3D design today!